SC PALLET REPAIR DEPOT

WOOD WASTE RECYCLING & REPURPOSING SYSTEM

SOUTH CAROLINA

We were contacted by a wood pallet repair depot in South Carolina to help them with their wood pallet trash problem. They were spending a lot of time and money on taking their wood waste to the landfill. Not only was this expensive and time consuming but it also had a negative impact on the local environment and landfill. Being a responsible company and a good steward to their local community, this company sought out the help of Boulware Equipment to help them with this problem.

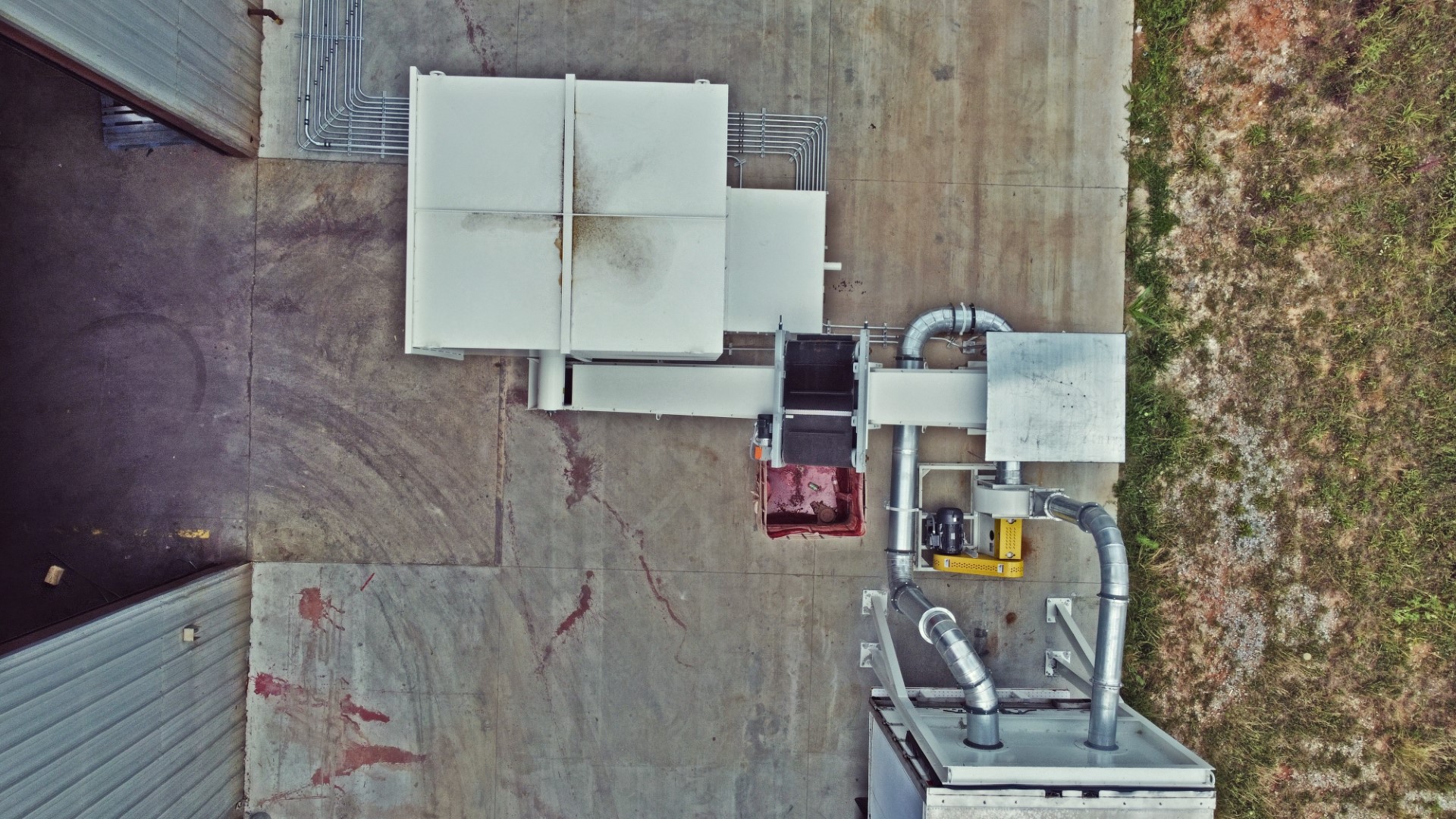

To eliminate the costs and time associated with their wood trash we installed a rebuilt Cresswood XR600-75 Wood Grinder along with a customized system required to merchandise the clean wood fiber product in bulk.

This system allows the company to dump their wood trash, complete with nails, into it and it cleanly grinds up the wood into a reusable product that can be sold. This product is mechancially moved into an awaiting trailer. On top of this, all nails and metal are seperated from the wood into a holding bin so they can be recycled.

This capitol investment gave the company an immediate return and produced a product that can be repurposed sustainably.

LEARN MORE ABOUT OUR WOOD WASTE SERVICE

FIELD SERVICE

Do you have a wood waste or dust collection system in place but it is in desperate need of servicing? Has your system broken down and is in need of repair? We can do a site survey and provide service, repair, or replacement as needed.

SCRAP REPURPOSE

All of our automated wood waste/pallet grinding systems have a repurposing element built into them to convert the processed scrap into a usable material that can be sold and reused. This ensures that there is no waste and zero material going to a landfill. This not only eliminates the costs of disposing of waste but it also gives you a sustainable solution for it that can also make you money.

TURN-KEY INSTALL

We will visit your facility to assess what needs you have when it comes to the disposal of wood waste, wood pallets, or dust. We will then design, engineer, and install a system on-site that will automate the disposal of wood waste/wood pallets or dust. The whole process will be handled by our professional team.

SCRAP RECLAIM

We develop reclaim strategies to help you to convey wood scraps, chips, boards, and just about any other wood/pallet waste to a grinding system. We will develop fully automated conveyor system using belts, blowers, and a variety of other methods to move scrap out of your facility and into the grinding or collection area.

WOOD PALLET WASTE SOLUTIONS

We design, engineer, and build systems at your facility that will take your scrap wood and scrap pallet wood and repurpose it into a material that can be sold to other industries. Our system will process your scrap wood, separate the nails and other metal with 99.99% efficiency from the wood, and then send the repurposed material into a trailer to be sold. All you have to do is load the wood into the system and turn it on! These systems are 100% turn-key, we build and install the systems. We develop custom, electrical control centers for you to be able to maintain and control this systems.

DUST COLLECTION SOLUTIONS

We provide solutions to help businesses move and collect waste dust from their facilities. These systems are 100% turn-key. We visit your site and then design, engineer, and install a system on-site that will move the dust out of your building and into a collection system. We have numerous automated options available to push, pull, and suck the dust out into a collection system. Every system comes with a electrical, control cabinet to monitor and fully control all processes.

WOOD PALLET WASTE & DUST COLLECTION EQUIPMENT

Wood/pallet waste and dust collection systems are complicated and require preventative maintenance. These parts will need service and repair. Boulware is an Avetta certified service and repair company for these systems.

OUR PROCESS

Our systems are complicated but our process is simple. We first conduct an email/phone consultation with you to get an idea on what you need. We then visit your facility in order to properly assess the situation. After that we draw up the plans for the system and do all necessary engineering to ensure it will work with your process. We then construct the system on-site to make sure that it fits. We then create the electrical control system and provide training to staff to operate it.